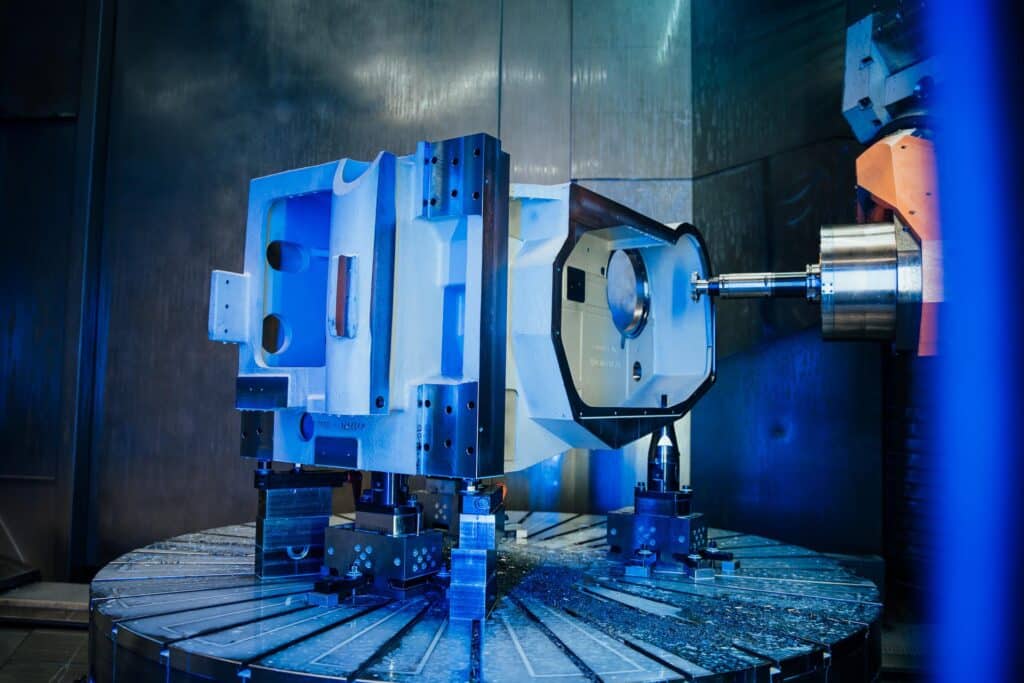

5-axis machining technology has been the primary machining strategy for many years in our milling department. Our motto also applies here:

As much machining as possible in one clamping operation.

This increases productivity and enables high precision on the component.

On some milling machining centers, even turning and partial cylindrical grinding are now possible machining processes. In this department too, our machines are equipped with a wide range of options such as extended tool magazines, high IK pressures, heat compensation, measuring probes, precision packages and much more. A wide variety of angle heads and additional axes enable us to produce highly complex geometries. On some machines, pallet changers shorten workpiece changeover times and increase machine running times with less manpower.

In addition to our high-quality machine tools from well-known manufacturers, the temperature control of our machine shops also improves compliance with high levels of accuracy in production.

Milling shop at a glance

- Prismatic components up to dimensions of 4000x1000 mm

- 5-axis complete machining from the smallest dimensions up to sizes 2200x2200x1400 mm

- Milling-turning complete machining up to a diameter of 2400 mm

- Unit weights up to 5t

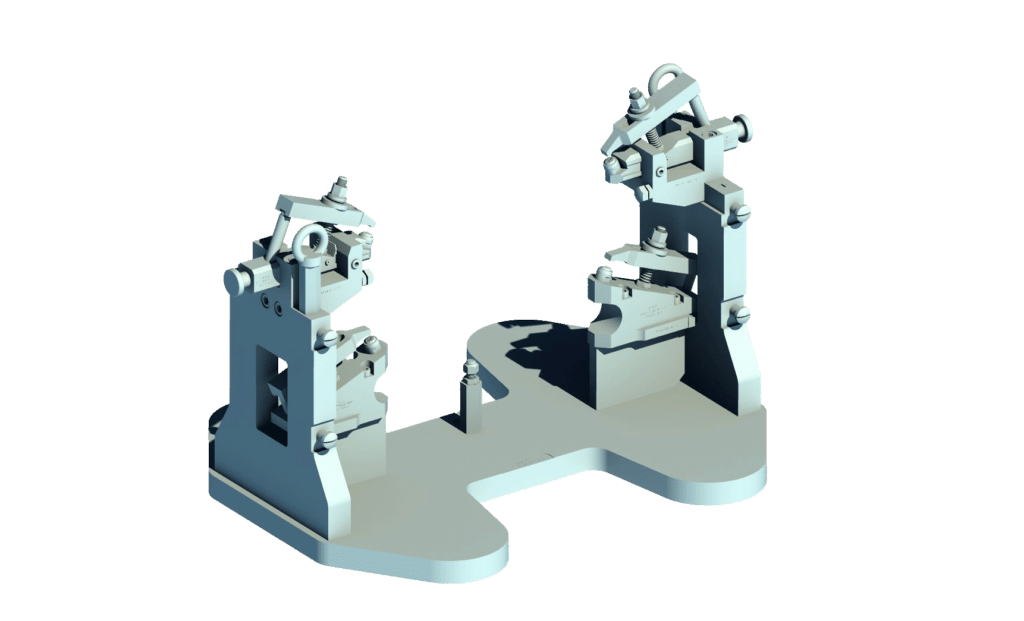

- Wide range of workpiece clamping options, e.g. magnetic and vacuum clamping technology

- Extensive range of tools and equipment

- Production of individual items and larger series

Our machinery in the milling department

Satisfied customers and satisfied employees are our aspiration

Modern manufacturing with TopSolid'CAM

The CNC programs are created in our CNC programming department using the CAM system TopSolid CAM from the customer data, simulated and transferred to production.

Before machining begins, the complete tools belonging to the CNC programmes are assembled, measured and prepared for production on the machine tool in the tool presetting department.