Over the last 15 years, our traditional turning department has increasingly developed into a center for complete machining. The core of our manufacturing capabilities in this department are five WFL MillTurn turn-mill centers, from M50 to M120, richly equipped with many manufacturing options.

Turning lengths from 3m to 6m, one or two steady rests also for machining slim shafts and rollers, magazines for large boring bars, system boring bars, angular milling heads for complex internal machining, options for coolant systems for deep hole drilling and much more.

We have a turning/milling center with counter spindle for the production of chuck parts up to 500 mm in diameter in batch sizes from 20 pieces.

A large number of smaller and larger CNC lathes with driven tools and two cycle lathes round off our options for manufacturing a wide range of rotationally symmetrical rotationally symmetrical components.

In addition to our high-quality machine tools, the temperature control in our machine shops enables us to maintain high levels of precision in production.

Turning shop at a glance

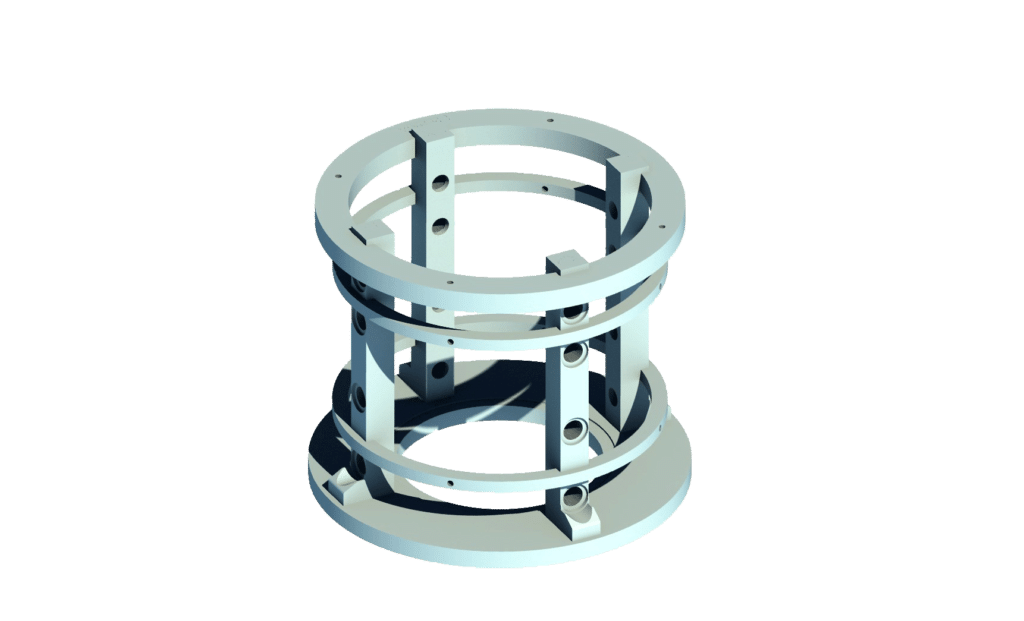

- Complete machining of shafts, rollers and axles of the smallest dimensions up to Ø 1100 mm, length 6000 mm

- Unit weight up to 10 t

- Complete machining of chucked turned parts up to Ø 1100 mm, up to 2400 mm in the milling department

- Complete machining of chuck parts in batch sizes from 20 pieces, up to Ø 500 mm on Index counter-spindle machine

- Chuck turned parts from Ø 10 mm to Ø 700 mm

- Single part and series production

Our machinery in the turning department

Satisfied customers and satisfied employees are our aspiration

Modern manufacturing with TopSolid'CAM

The CNC programs are created in our CNC programming department using the CAM system TopSolid CAM from the customer data, simulated and transferred to production.

Before machining begins, the complete tools belonging to the CNC programmes are assembled, measured and prepared for production on the machine tool in the tool presetting department.

Why Kersten Maschinenbau is the right partner for your turning and milling work

Kersten Maschinenbau is your competent partner for turning and milling work. Thanks to our many years of experience and expertise in the industry, we manufacture precision turned parts to the highest quality standards. Our company is characterized by state-of-the-art manufacturing technologies and high-precision machines that ensure efficient production. We offer customized solutions that are individually tailored to the needs of our customers. The high level of expertise of our employees and first-class customer service round off Kersten Maschinenbau’s profile as a reliable and competent partner.

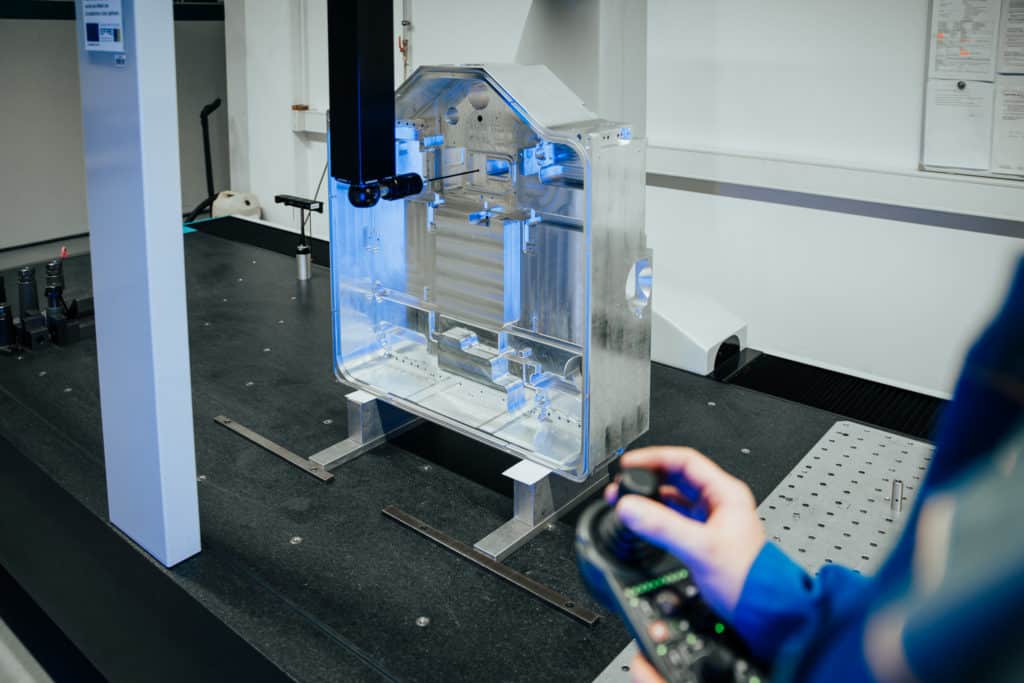

Highest quality: not only manufacture, but also measure

At Kersten Maschinenbau GmbH, we rely on a combination of modern measuring technology and meticulous quality assurance to ensure the highest precision and quality in the production of our turned parts. In addition to detailed final inspections, we ensure quality assurance of our precision turned parts during the production process in three shifts. Each part is checked for dimensional accuracy and surface quality using high-precision measuring machines. The measurement results obtained allow us to take immediate corrective action if deviations are detected, thereby stabilizing the production processes.

- 3 coordinate measuring machines with measuring range up to 6000 x 3000 x 2000 mm

- Scanning probes for contour measurement

- Fully air-conditioned measuring room

- Over 6000 measuring and testing devices in stock

- Roughness measuring devices

- TÜV re-stamping authorization for several employees

- Certification according to ISO 9001:2015

Components for agricultural machinery

In tractors and harvesters, for example, precision turned parts are used for important components such as transmissions, engines, axles and hydraulic systems. These parts have to withstand high loads and extreme operating conditions, which is why their precision and quality are of crucial importance. They ensure that all mechanical movements can be carried out smoothly and accurately, which contributes directly to the productivity and longevity of the machines. Especially in hydraulics, where exact controls and movements are required, precisely manufactured turned parts ensure reliable operation.

Turned parts for railroad technology

Precision turned parts play a crucial role in railroad technology to ensure the safety, efficiency and reliability of trains and rail systems. They are used in various key components, including running gear systems, brake systems and couplings. In running gears, they ensure the exact fit and smooth functioning of axles, bearing housings and suspension systems. In brake systems, they enable the precise control and actuation of brake disks and brake pads, which is crucial for the safety and performance of the trains. Coupling systems, which are responsible for connecting and disconnecting towing vehicles, also contain precisely manufactured turned parts to ensure a reliable and safe connection.

Oil and gas industry - the use of accurately manufactured turned parts

In the oil and gas industry, precision turned parts are used in various applications to ensure efficiency and safety. These parts are required for a variety of critical components, including valves, pumps and compressors used in production systems and refineries. They are also used in drilling rigs and production platforms, where they must withstand high pressure and temperature conditions. They are also essential for the manufacture of connectors and seals used in pipelines and delivery lines to prevent leaks and material fatigue. The high precision and reliability of these parts ensure that the complex systems used in oil and gas production function smoothly, minimizing downtime and thus increasing operational efficiency.

Precision turned parts in force measurement technology

To ensure the accuracy and reliability of the measuring systems, precision turned parts are used in various components of force measuring devices, including sensors, actuators and fastening elements. They ensure that the mechanical connections in the measuring systems are accurate and stable, which is essential for the correct transmission and measurement of forces. Precision turned parts are used in force sensors to stabilize the sensitive measuring points and ensure high reproducibility of measurement results. They also help to protect the sensors against external influences such as vibrations or temperature fluctuations. In actuators that exert forces on samples or structures, precision turned parts ensure precise control and movement guidance.