Kersten Maschinenbau stands for quality, reliability and flexibility – for over 25 years. From individual parts to assemblies.

With over 120 skilled workers and engineers, we have a wealth of technological experience at our disposal

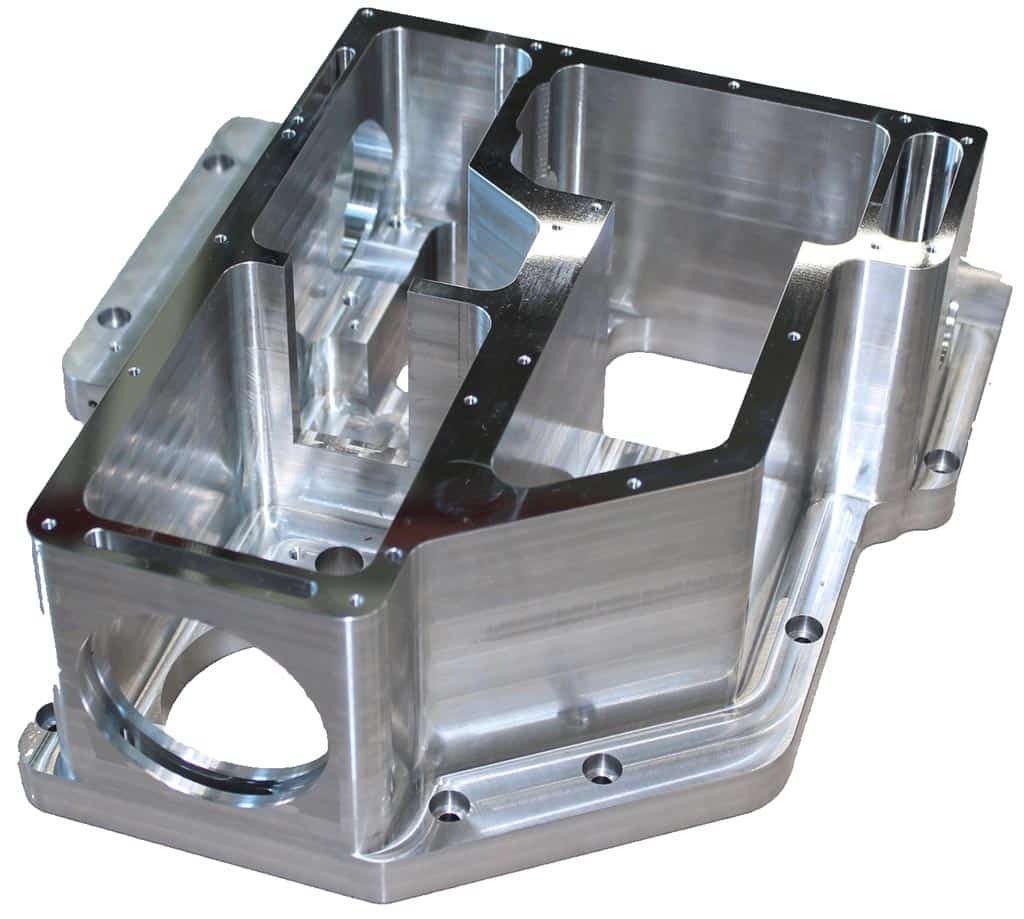

Thanks to our modern and high-quality machinery, our precise measuring technology and the expertise of our teams, we offer the highest level of precision and quality

Die Kersten Maschinenbau GmbH, in Niederau OT Ockrilla bei Meißen, in der Wiege Sachsens, fertigt Maschinenbauteile und Baugruppen, in höchster Präzision und Qualität.

Mit dem Fokus auf die Anforderungen und Wünsche unserer Kunden entwickeln wir Technologien zur Herstellung anspruchsvoller komplexer Maschinenteile und mechanischer Baugruppen, die wir auf unserem umfangreichen Maschinenpark umsetzen.

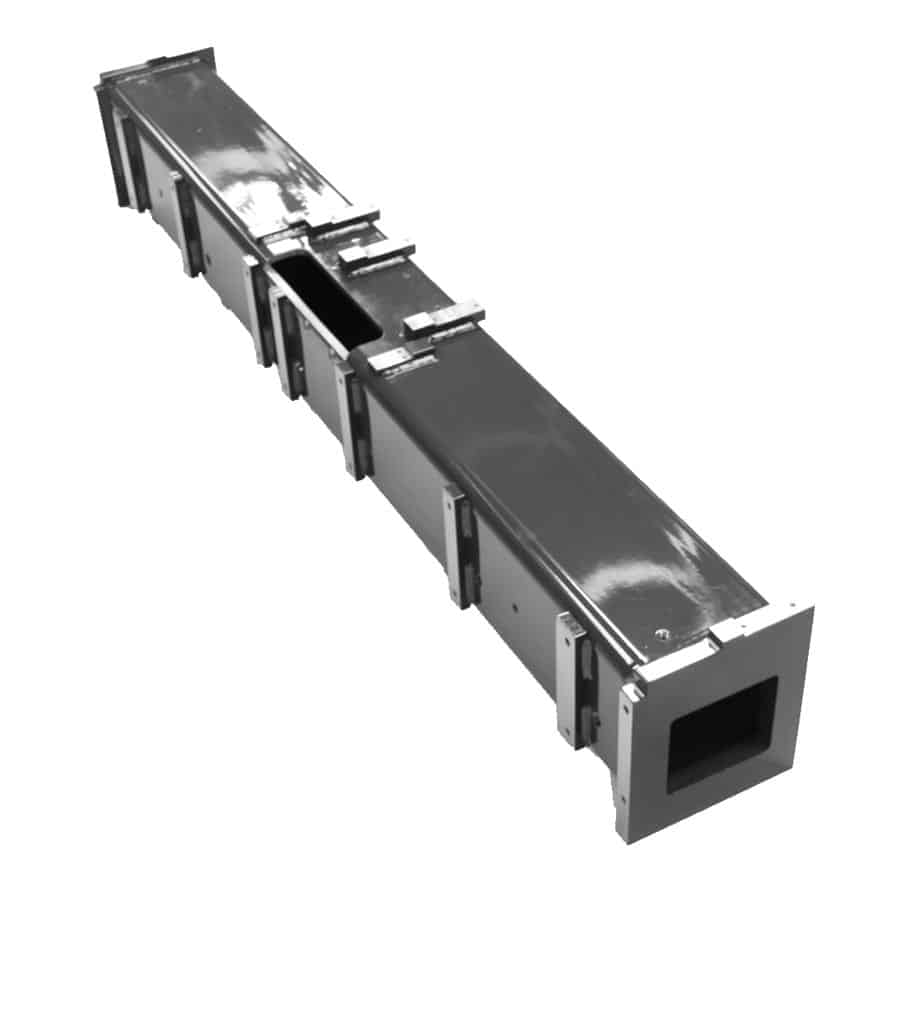

Mit den klassischen Bearbeitungsverfahren Drehen, Fräsen, Schleifen und den modernsten Technologien der Komplettbearbeitung sind wir die Profis der Zerspanung. Das Schweißen und die Wärmebehandlung im eigenen Hause ermöglichen uns ebenso die Herstellung von Schweißbaugruppen aus unterschiedlichsten Materialien mit anschließender mechanischer Bearbeitung.

Mit unserem Einkauf und einem breit aufgestellten Netzwerk an Lieferanten und Kooperationspartnern stellen wir die Beschaffung der verschiedensten Rohmaterialien, ob Stangenmaterial, Brennteile, Gussteile oder Schmiedestücke sicher und ergänzen unsere Fertigungsmöglichkeiten durch vielfältigste Verfahren der Wärme- und Oberflächenbehandlung. Our customers receive ready-to-install machine parts or assemblies, manufactured using all the necessary technologies.

You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More InformationThe manufacturing costs of the components are determined on the basis of customer drawings and 3D models. Our customers then receive our offer, stating the price and the best possible delivery time.

Once the order has been received, all the necessary master data for the items the parts lists and the customer order are created in the PPS system and the customer receives our order confirmation.

All raw and purchased parts required to manufacture the components are put out to tender in our broad network of suppliers and purchased in a quality and cost-conscious manner.

The technological production process is worked out, the optimum cutting tools are selected, clamping plans are created and the CNC programs are generated with the help of TopSolidCAM.

All components are available to us virtually to simulate CNC machining: the 3D models of the clamping devices and complete tools as well as the digital twin of the processing machine.

In a three-shift system, the components pass through the various production steps in the corresponding batch sizes, scheduled and controlled via our production control center.

Real-time production data acquisition ensures that the planning data is up to date. This transparency of the production process enables us to permanently monitor deadlines with the aim of achieving the highest possible adherence to delivery dates in the interests of our customers.

Our quality assurance department monitors compliance with all quality features across all three shifts during production and, once the components have been completed, creates all the necessary protocols and documents that document compliance with the product parameters.

The components are properly preserved and packaged, stored at the customer's request if necessary and delivered to the customer on time using our own transport vehicles or by a forwarding agent.

All operational procedures and processes are organized via our ERP system PPS2000.

In addition to the classic ERP functionalities, such as quotation preparation, order management, procurement, storage and shipping, our PPS2000 has a detailed production planning and control system with a production control center and comprehensive production data acquisition.

With these prerequisites for permanent deadline monitoring, we ensure maximum delivery reliability.