Kersten mechanical engineering: Made in Germany

Since the company was founded in 1965, we have been active in mechanical engineering and the manufacture of machine components.

With a strong team of over 130 employees, we manufacture ready-to-install machine parts and assemblies in a 3-shift system for a wide range of customers from various branches of industry. Our customers export to many countries meaning our components can be found in a wide variety of machines and systems all over the world.

Our range of services

- Complex prismatic and rotationally symmetrical components, ready for installation, incl. Heat and surface treatment

- Welded assemblies, mechanically processed

- Fixture construction with in-house CAD design

- Component weights from 10 grams to 10 tons

- Component dimensions from 6 millimetres to 6 meters

- Batch sizes from 1 piece to 5000 pieces

Our services

- Technological and constructive support

- Procurement logistics for all raw parts, e.g. molded castings, forgings, flame-cut parts, bar material

- Just in time deliveries

- Free delivery

- Warehousing for customers

- Call-off orders

Our strengths

- Flexible and customized order processing

- short delivery times

- Broad production spectrum

- Highest quality standards

- Permanent deadline monitoring

- More than 50 years of experience in mechanical engineering

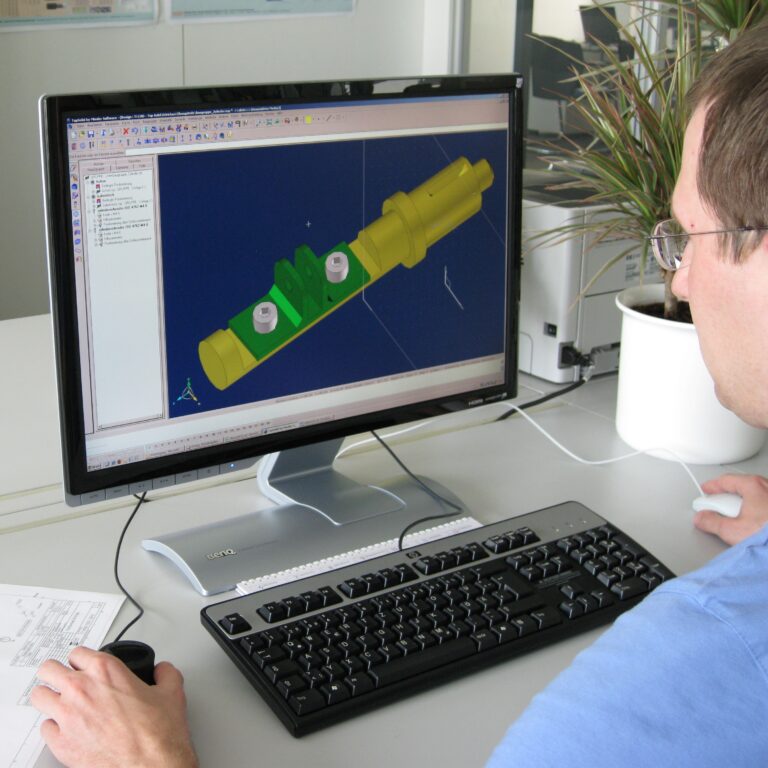

- CAM system optimized manufacturing process

Our performance

- more than 130 experienced skilled workers, technicians and engineers

- 10 trainees

- Over 40 processing machines

- over 9000 m² production area

- own delivery vehicles

- DIN EN ISO 9001 - 2008 certified

- authorized to be restamped by the TÜV

Our history

On 01.02.1965, Mr. Ing. Heino Kersten took over Paul Schümichen's "Maschinenbau Handwerksbetrieb" and founded the "Spezialwerkstätten für Sondermaschinen Ing. Heino Kersten" at Nicolaisteg 2 and 7 in Meißen.

The small private company was able to operate somewhat more independently of the GDR planned economy.

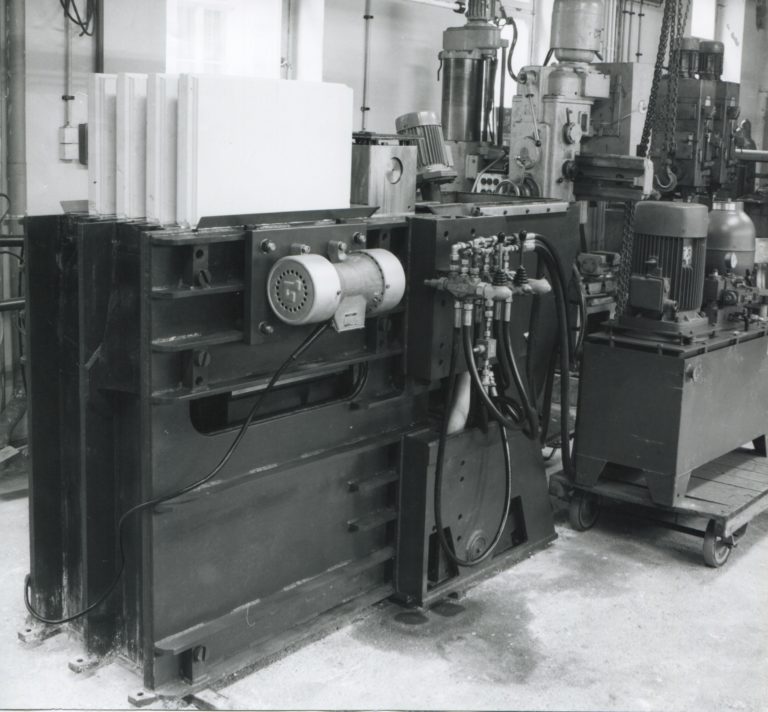

We designed and built special machines for projects of institutes and VEB companies for which the planned economy did not provide any balance sheets.

- Test press

- Gluing machine for wooden strips

- Glass cutters for the ceramics industry and much more

- Own product: Small woodturning lathe

The previously rented company premises at Nicolaisteg 7 were purchased and work started on renovating the building, and larger contract projects were accepted, e.g.

- Automatic production plant for concrete windows (Coswig concrete plant)

- Shaping machine for the production of plasterboard

- LPC plant for the production of concrete floor elements (Kerbe Meißen construction project)

- Scissor lift tables for truck loading ramps

- LFA wastewater treatment plants for the Baltic Sea ports of Rostock and Mukran

- Work was also carried out for medical technology: HFD200

- Our series production at the time: base frames for traffic mirrors

With the progressive decline of the former GDR economy and the arrival of the market economy, the entire previous customer base dissolved.

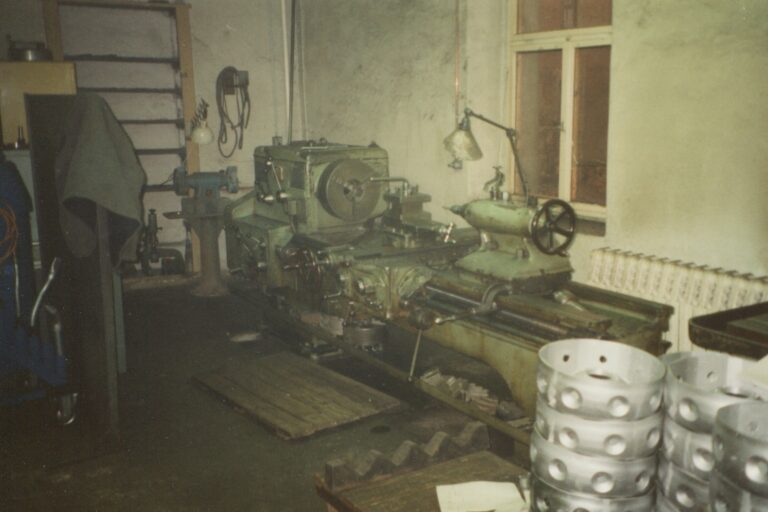

Due to the GDR's economy of scarcity, the company's technical equipment was outdated and uncompetitive.

The company began to invest in its first new machine tools:

- Heckert FU400 milling machine

- Lathes Berggießhübel DZFG200

- the first two Bridgeport Interact 720 CNC milling centers

The first CNC lathe DFS2/2 and a large surface grinding machine

were purchased as second-hand machines.

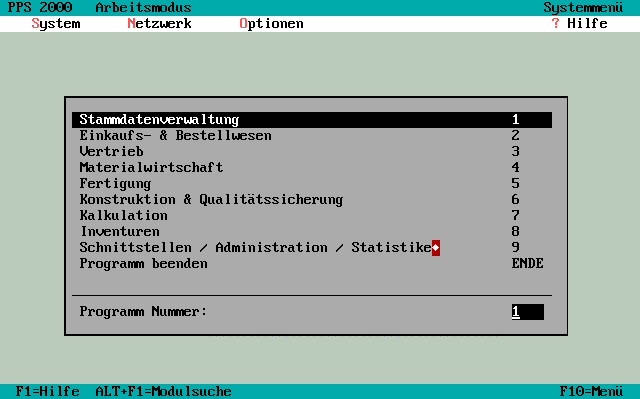

The first version of PPS2000 was introduced for production planning and order processing, at that time still with a DOS operating system.

The parking lot adjacent to the company premises on Neumarkt was purchased

and two new halls for the turning shop and welding shop were built on it.

The turning shop was equipped with 4 brand new CNC lathes from Boehringer and Monforts. The space freed up in the milling shop was used to invest in our first Hermle C800U 5-axis milling machine.

The switch to the new PPS2000 Windows was made just in time for the millennium.

Catastrophic damage was caused by the double flooding in August 2002.

First, the small river “Triebisch” adjacent to our property burst its banks at breakneck speed and flooded the entire company in a short time.

Just a few days later, the Elbe's flood of the century pushed the course of the Triebisch upstream and flooded the company headquarters again.

After the catastrophic damage caused to our company by the floods in August 2002, it was necessary to organize the fastest possible resumption of production through short-term measures and to draw up a concept for the long-term development of the company.

The repair of the flood damage began immediately after the water receded. Thanks to the strong commitment of the entire workforce and many volunteers, the premises at Nicolaisteg were prepared to such an extent that the new C800U, delivered at short notice thanks to the rapid assistance of Hermle, could already be put into operation in October.

A hall was rented in the Ockrilla industrial estate in order to be able to set up the new machines, which continued to arrive, in a flood-proof location.

The company “Heino Kersten Sondermaschinenbau” was transformed into “Kersten Maschinenbau GmbH” at the beginning of 2003. Mr. Heino Kersten left the company for reasons of age and Mr. Jürgen Hinz joined the company as managing partner alongside Mr. Udo Kersten.

With the purchase of the property Ockrilla Gewerbegebiet Nr. 5 of the former heating and sanitary wholesaler “Der Schaff” in July 2003, the company acquired a property which, with its size of approx. 5000m² of production space provided an ideal basis for further development.

After the necessary conversion work, we were able to move in in mid-2004

and complete the work by December.

At the same time, we invested in our first Unicen1000 turning/milling center from Monforts and the first large 5-axis moving column milling machine.

In order to meet the growing customer demand for larger parts, particularly in the wind turbine sector, we began a new investment project in 2005.

The main investments were the turning/milling center WFL M65x4500 and the first CNC cylindrical grinding machine HG72-3000.

In order to secure the company's future expansion possibilities, the hall rented after the flood and returned in 2004 was purchased in industrial estate no. 12.

The introduction of the CAD and CAM software TopSolid for offline programming of our diverse production machines was a major step forward for our work preparation.

Digitalization in production began at the same time as the first production data acquisition devices were introduced. In addition, the introduction of the PPS2000 production planner enabled consistent production control and permanent deadline monitoring.

The intensive investment activity of recent years meant that by the end of that the space in the hall was already exhausted by the end of 2009.

Despite the somewhat difficult economic times in 2008/2009,

was constantly thinking about the next development steps. The customer base, which had continuously expanded in recent years, developed new machines and systems, which were often larger and more productive and therefore required larger and more precise components.

In order to keep pace with this development, we planned the most extensive investment project in the company's history to date.

The first step was to convert hall no. 12 into a welding shop

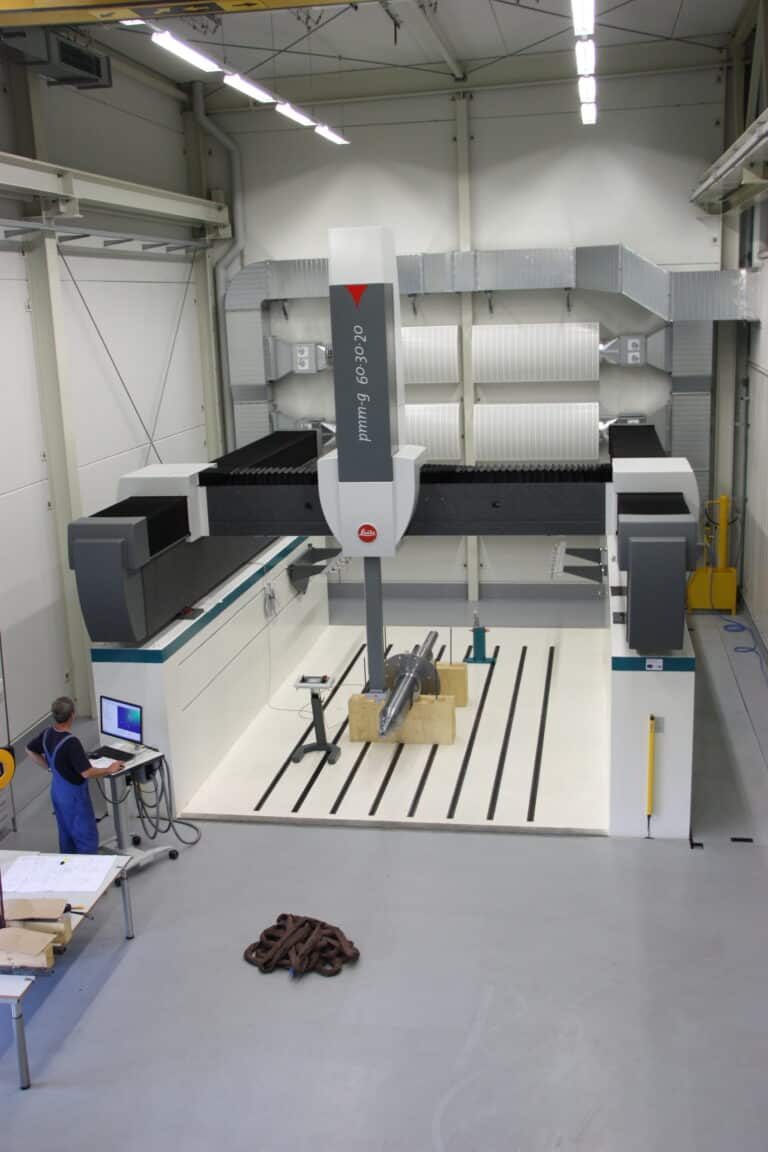

and expand it with a new 940m² hall for incoming goods and cutting. A new 2300m² hall for the turning and grinding shop and the 290m² air-conditioned measuring house were then added to our main hall.

The large Leitz PMM-G 603020 coordinate measuring machine was installed here.

The WFL M120x6000, WT72x6000 cylindrical grinding machine and the large annealing furnace went into operation in the new large hall.

The former areas of the turning/grinding shop that had become vacant were assigned to the milling department and equipped with the new Alzmetall GS1400 and Reiden RX18 milling/turning centers.

With the extensive investments in machinery and equipment, the total investment amounted to over €13 million.

Further investments were also made in the years 2014 to 2023.

Turn-mill machining was expanded with a new WFL M80x4500 in 2018 and a WFL M50x4500 in a WFL M50x4500 in 2023.

Mill-turn machining was expanded in 2017 with the second Alzmetall GS1400. At the beginning of 2023, our cutting department was modernized with two new automatic band saws.

In May 2023, we put our first machine with pallet changer into operation. The Hermle C52U MT with 8-fold pallet changer PW3000 is a new milestone for us in the direction of automation.