You are currently viewing a placeholder content from Youtube. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information

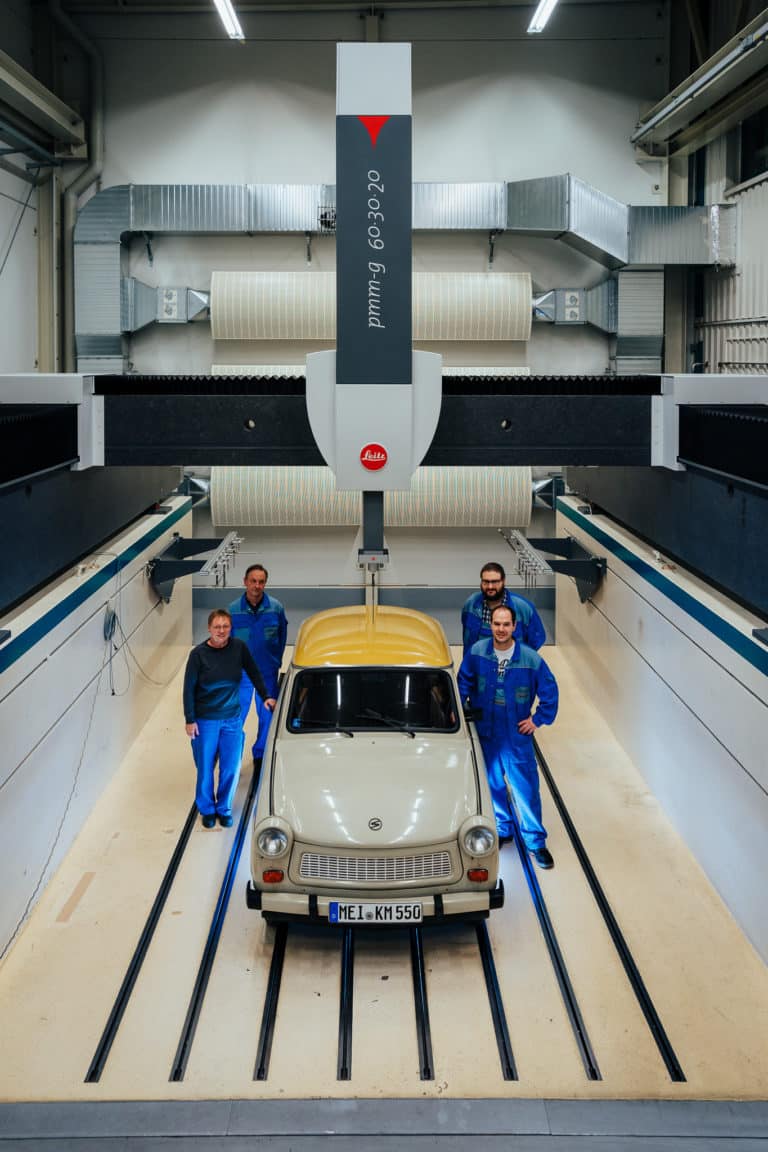

Since our foundation in 1965, we have been active in mechanical engineering and the production of machine components. With an experienced team of over 130 employees, we offer a stable working environment and exciting challenges in a growing company. Our high level of expertise and our international customer projects guarantee varied tasks and long-term development opportunities. Become part of our successful team and benefit from an environment that promotes your professional development.

You need to load content from reCAPTCHA to submit the form. Please note that doing so will share data with third-party providers.

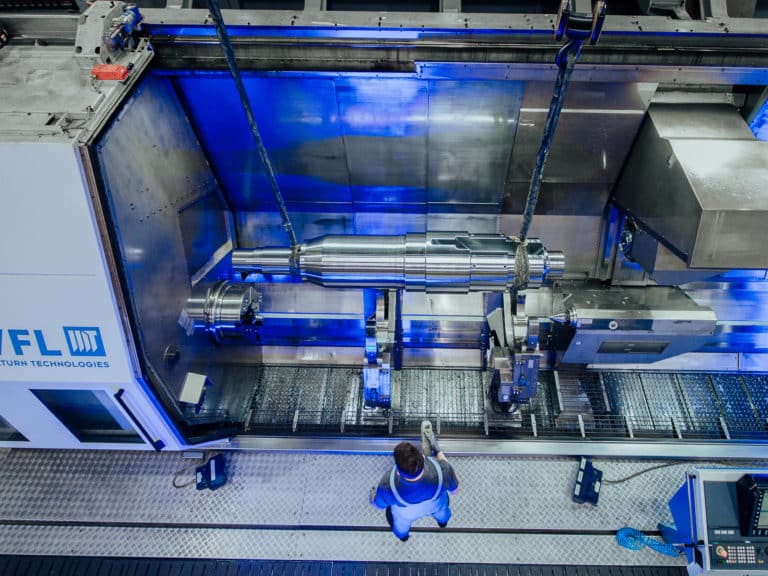

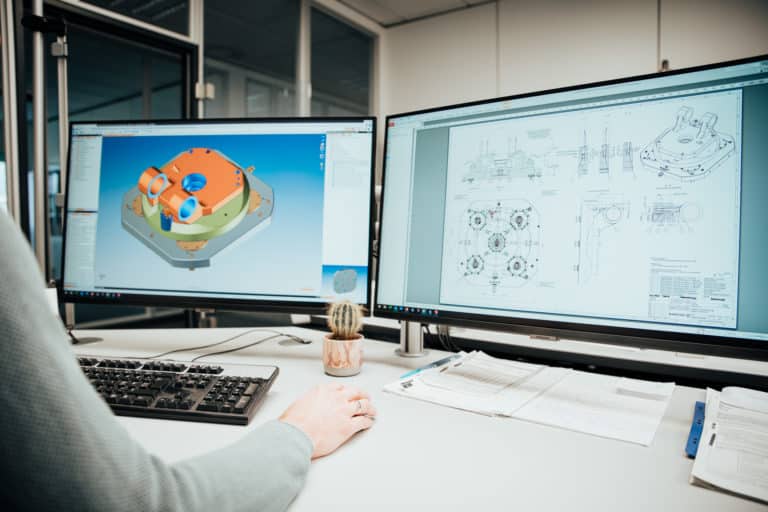

More InformationTechnical know-how meets strong spatial awareness and a deep understanding of mathematical relationships.

As a cutting machine operator (m/f/d), you are a versatile expert in metalworking.

You will master the precise machining of sophisticated components on CNC lathes, milling and grinding machines and monitor every step of the machining process.

Through continuous quality checks and fine adjustments, you will ensure maximum precision and compliance with the strictest standards.

This apprenticeship not only offers attractive shift allowances, but also excellent opportunities for further training and promotion as well as a fair and performance-oriented bonus model.

A profession with a future and diversity, in which you will be in demand in all areas of machining technology.